Power intelligent operational decisions

Streamline data collection and reporting. Leverage predictive analytics for improved decision-making and operational efficiency.

Book a demo

Trusted by industry leaders & innovators

Improve decisions with powerful quality data management and analytics

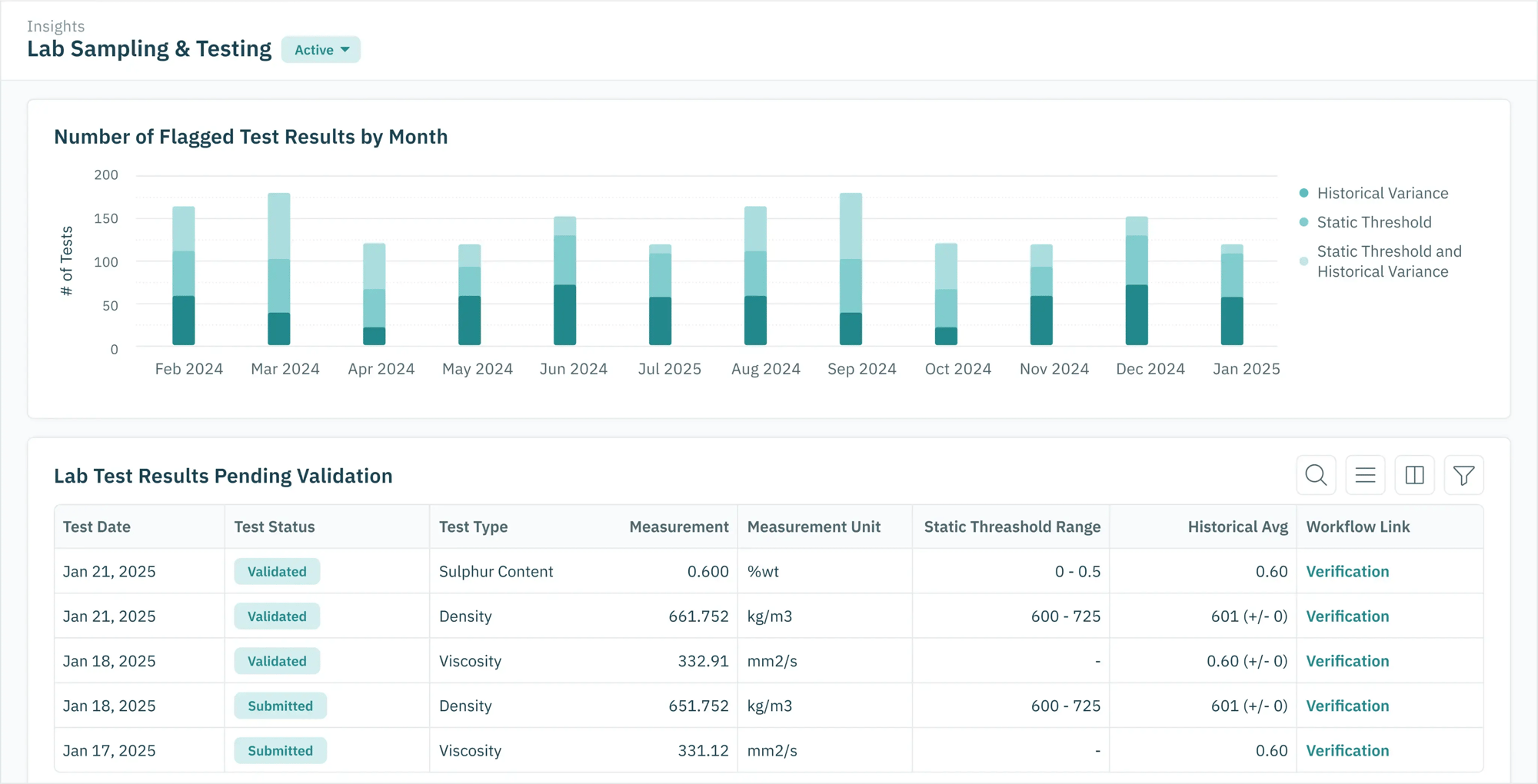

Comprehensive sample and quality management

Gather data from various sources and create a centralized control center to manage your quality and sampling programs.

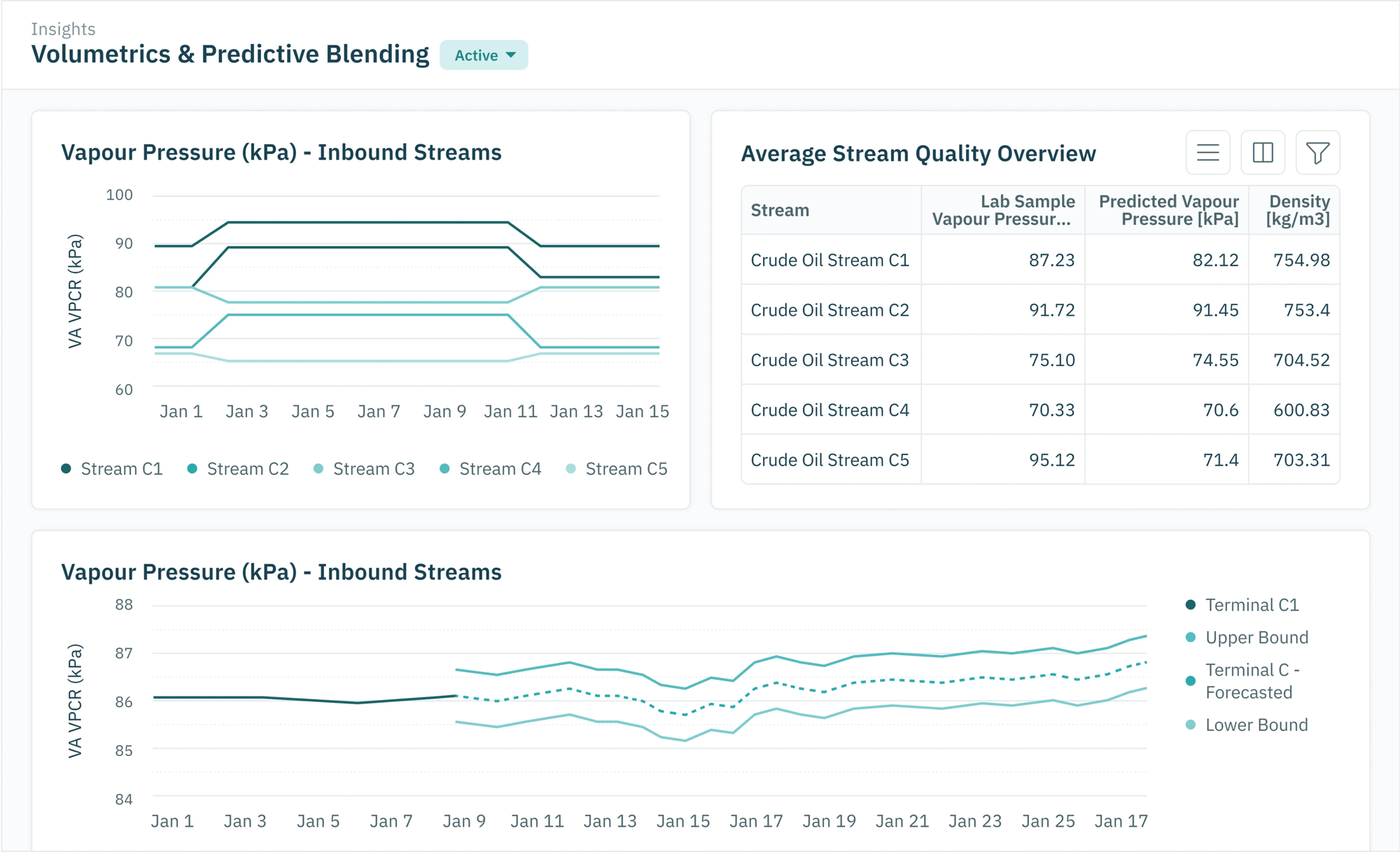

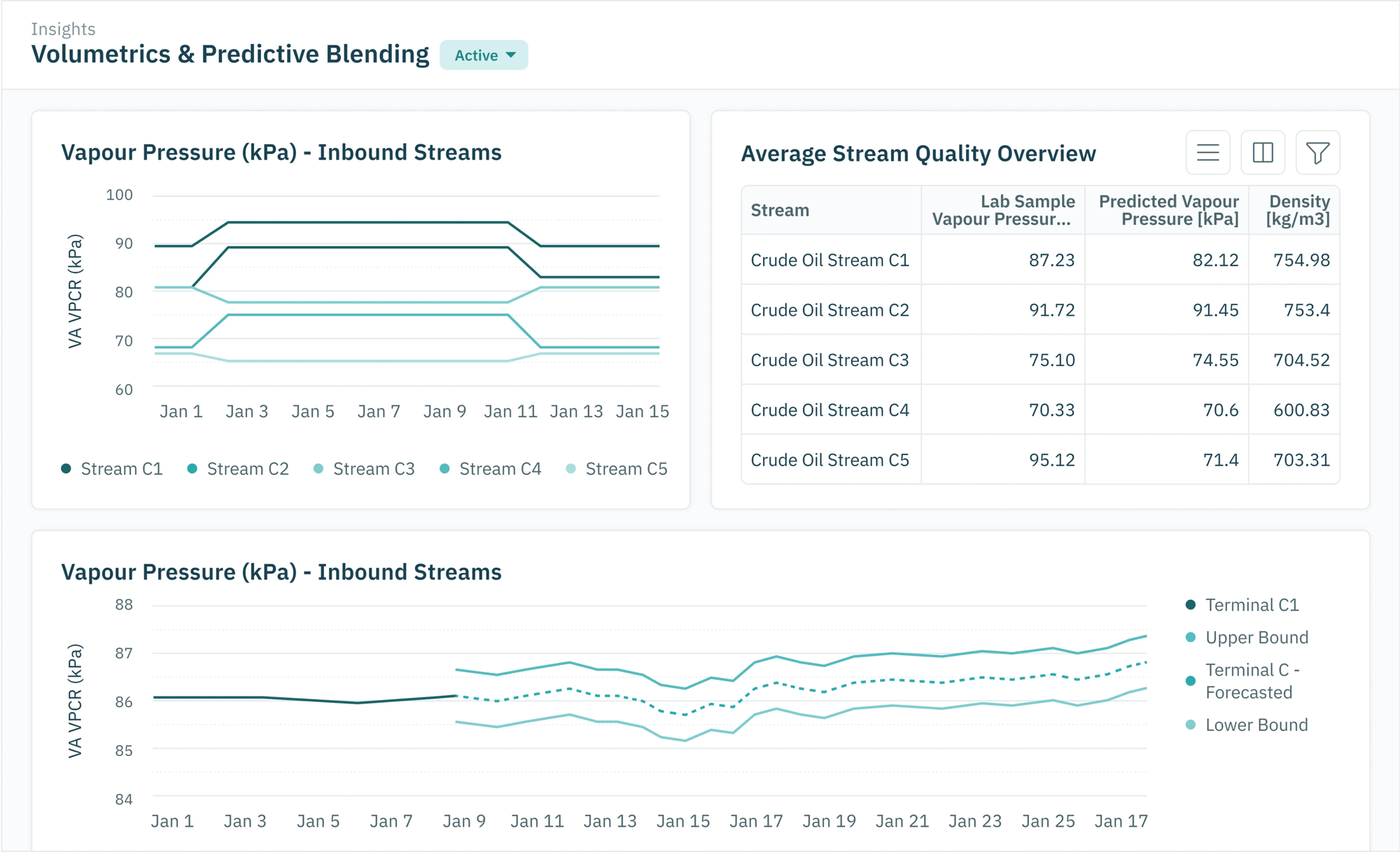

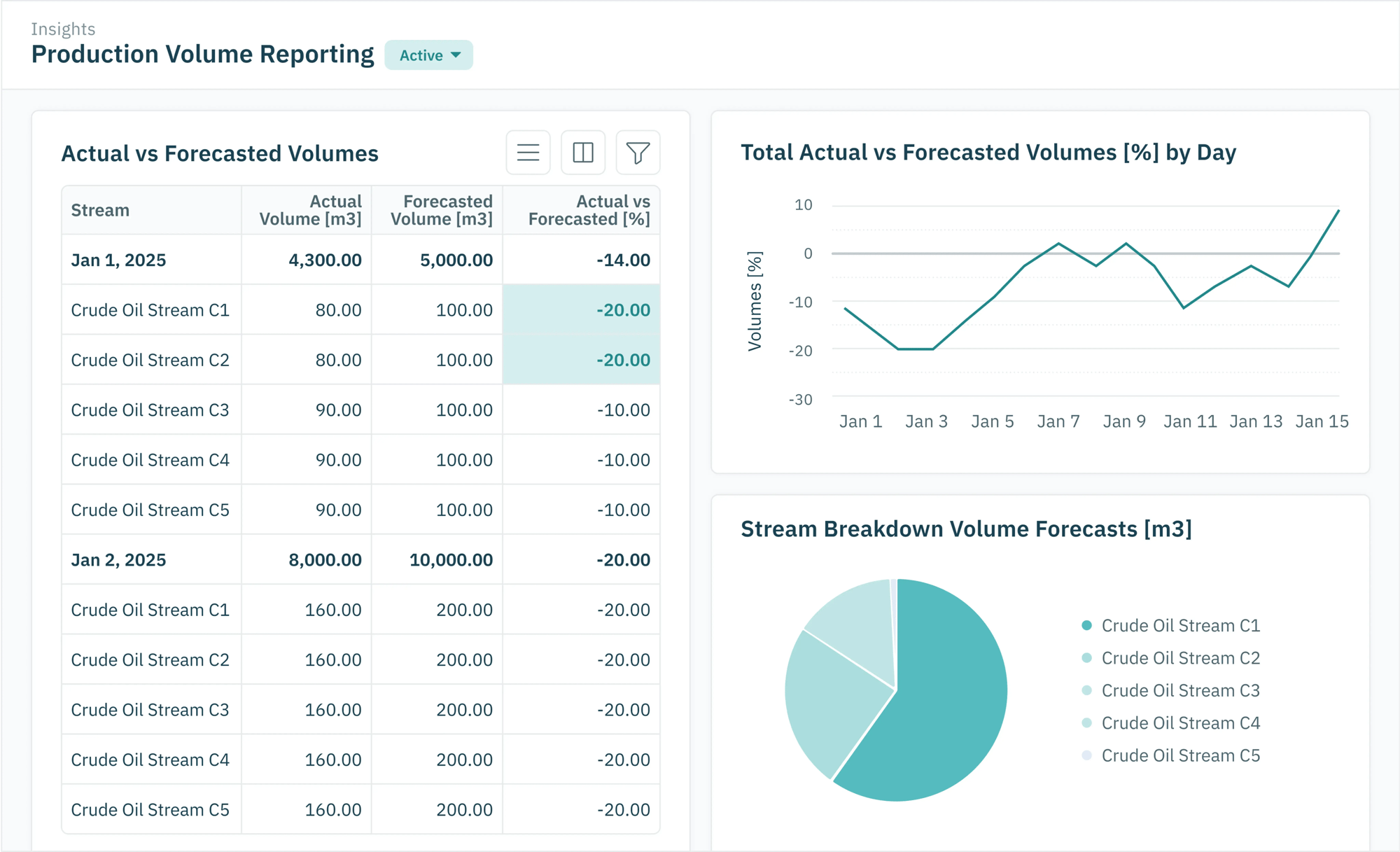

Learn MoreActionable and predictive insights

Leverage analytics built on real-world context to optimize your operations while improving efficiency.

Learn More

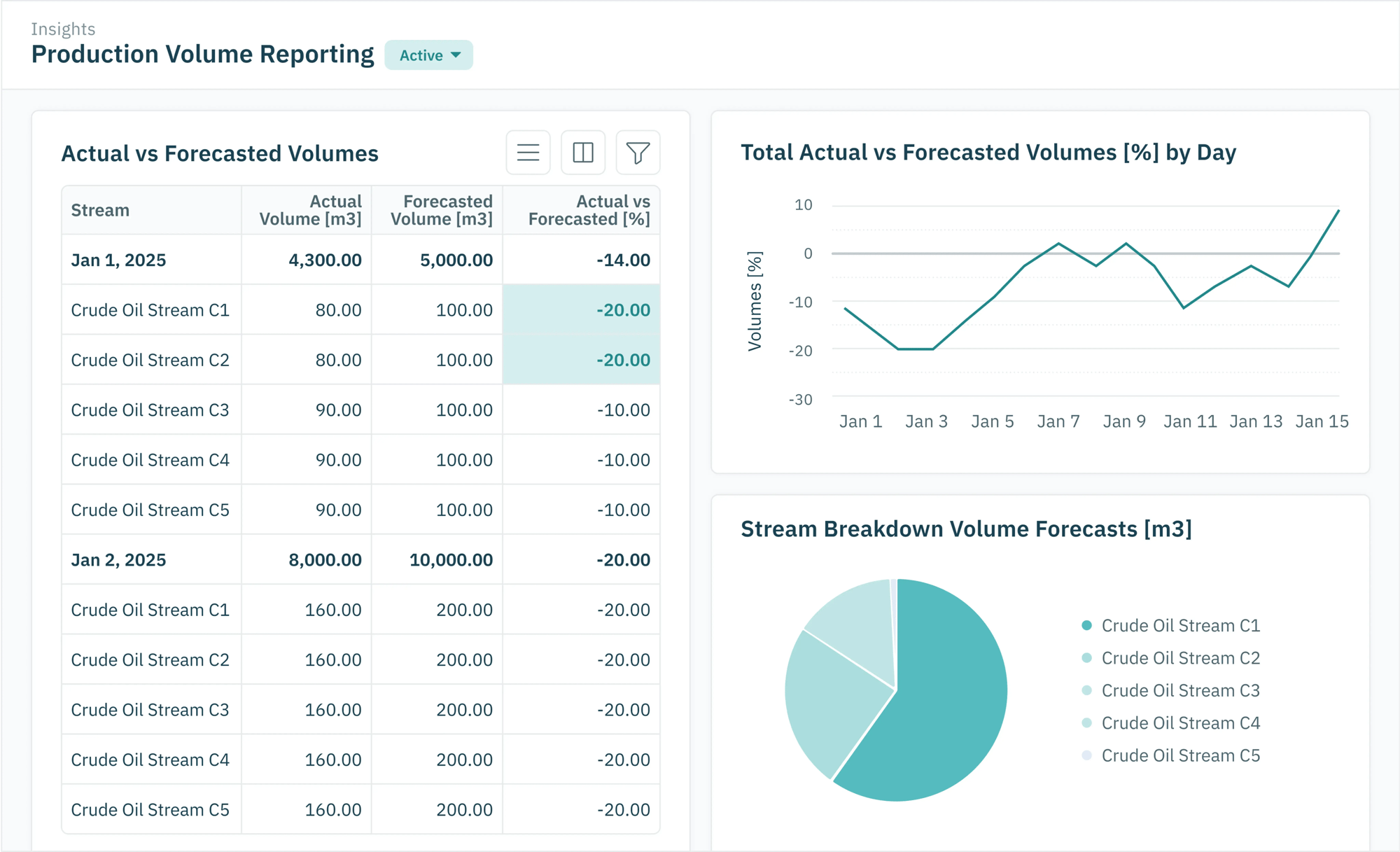

Consolidate volutmetric data for reporting and facility optimization